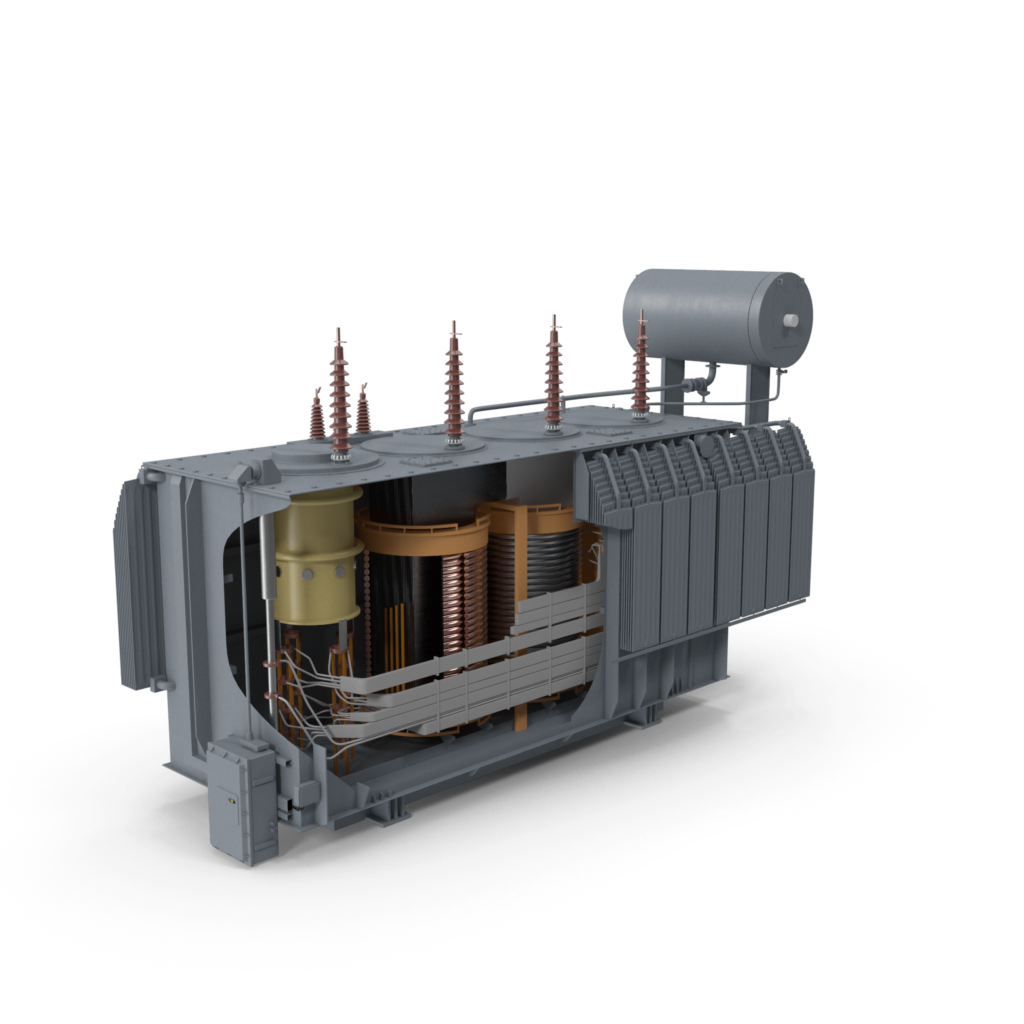

Regulated power transformers are essential in high voltage transmission grids for ensuring efficient and stable electricity transfer over long distances. They adjust voltage levels to minimize power loss, enhance reliability, and support consistent electricity supply. On-load tap-changers (OLTC), the only moving parts, are the heart of these transformers regulating the voltage by changing the turn winding ratio. This makes OLTCs critical components for maintaining optimal voltage, accommodating varying demands, and integrating renewable energy sources into the grid.

HVAC Test

We are experts in on-site HV testing!

For transformers we perform your applied voltage test up to 560kV!

OLTC Maintenance and Service

Proper Maintenance is crucial since OLTCs are the only moving parts in regulated power transformers. Proper maintenance by skilled technicians is essential, as even a single loose bolt can damage the entire transformer. Only regular professional service ensures smooth operation, prevents costly failures, and extends the transformer’s life.

Aspectus has more than 20 years of experience and maintained together with our partner MR more than 500 OLTCs in Singapore without any incidents.

With our great experience and proven track record we are your first contact for all kinds of services around on-load tap-changers!

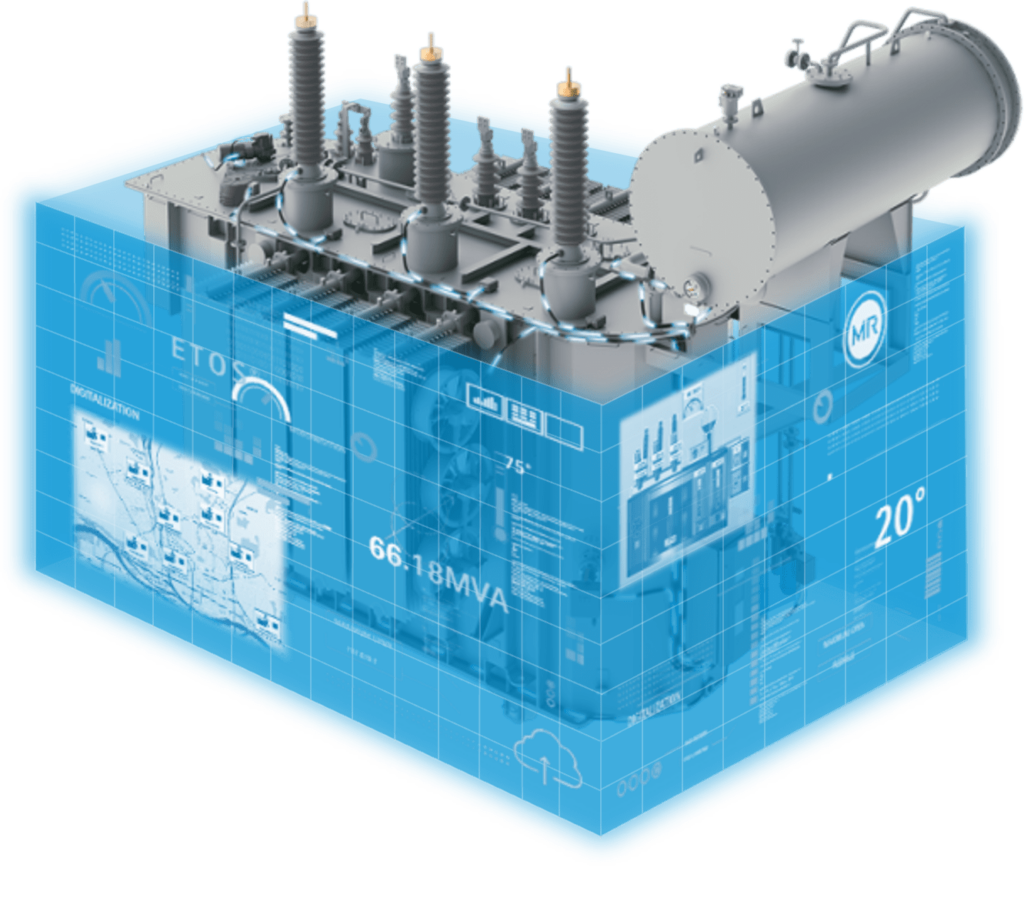

Automatic Voltage Control & Digitalization

The Automatic Voltage Control (AVR) known as TAPCON ensures precise voltage control, enhancing the stability and reliability of the power grid. It features advanced technology that allows for seamless on-load tap changing, ensuring minimal disruption and optimal performance.

Beside AVRs today’s digitalization of transformers allows various possibilities for automation and enhanced monitoring:

- Online Dissolved Gas Analysis

- Monitoring of Active Part, OLTC and Bushings

- Advanced Cooling Control

- Dynamic rating

We are your partner of choice both for new installs and retrofit/upgrade.

Condition Assessment

MR’s FleetScan 2D is a sophisticated diagnostic and monitoring tool for comprehensive condition assessment and predictive maintenance capabilities. It utilizes advanced algorithms to analyze data from various sources, to give a comprehensive picture on lifetime consumption and risk of the asset. This gives you a professional basis for your OPEX and CAPEX planning!

The algorithm provides a holistic assessment of your transformer by merging the data from different sources to form a comprehensive picture:

- Detailed and structured visual inspection

- Thermography

- Oil sampling results

- Electrical Measurements

By partnering with us to implement MR’s FleetScan 2D into your processes, you will enter a new era in asset management.

Electrical Testing

Low voltage electrical measurements are fundamental to transformer testing, serving as a crucial basis for Factory Acceptance Tests (FAT), Site Acceptance Tests (SAT), and ongoing condition assessments. These measurements provide essential data that ensure transformers meet stringent quality standards and perform reliably in the field. We are able to provide a wide range of measurements services, but especially we do conduct professional analysis of the gained results.

- Insulation Test Core to Winding

- Tan D of winding

- Ratio & Vector group

- No load current

- De-magnitization

- Excitation current

- Short Circuit Impedance / Leakage Reactance

- DC Winding Resistance

- Frequency Sweep Response Analysis

- OLTC Vibroacoustic measurement

- Dynamic resistance measurement

- Transient Earth Voltage

- Ultrasonic

- IR Thermography

- Temperature instruments calibration

- Insulation Resistance of Control Cables

Oil Quality & Dissolved Gas Analysis (DGA)

We provide you with a full package of sampling, analysis (by our certified partner lab in Australia) and database with trend analysis.

Curios for some more background information?

Transformer insulating oil serves several functions including insulation, cooling, and arc suppression. Over time, the quality of this degrades due to various factors such as oxidation, contamination, and thermal stress. Regular oil quality measurements help monitor these changes. Key parameters are:

- Dielectric Strength: Indicates the oil’s ability to withstand electrical stress without breaking down.

- Moisture Content: Water in oil significantly reduces its insulating properties and can cause deterioration of solid insulation materials.

- Acidity: High acidity leads to the formation of sludge and corrosion of transformer components.

- Interfacial Tension (IFT): Measures the oil’s ability to separate from water. In case of low IFT a oil reclamation may be required.

- Furans: Indicate the degradation of the paper insulation.

- Corrosivity: Oil must be non-corrosive both against copper and silver.

DGA is a technique used to analyze the gases dissolved in transformer oil. The presence and concentration of certain gases can reveal various types of faults or incipient issues. Key gases and their implications include:

- Hydrogen (H₂): Indicates possible sparking or corona discharge.

- Methane (CH₄): Often associated with low-temperature overheating.

- Ethane (C₂H₆) and Ethylene (C₂H₄): Indicate higher temperature overheating or thermal faults.

- Acetylene (C₂H₂): Suggests high energy arcing, which is a serious fault condition.

Carbon Monoxide (CO) and Carbon Dioxide (CO₂): Can indicate the degradation of cellulose insulation.

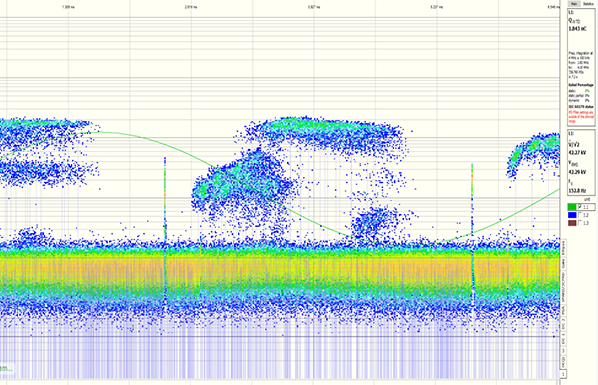

Partial Discharge Measurement

Partial discharge (PD) measurement is a critical diagnostic technique to detect small electrical discharges within insulation systems that can lead to insulation failure if left unchecked. We provide PD measurement services using Coupling Capacitors High-Frequency Current Transformers (HFCT) and ultrasound technologies, ensuring accurate detection and analysis.

Technical Training

Our training program covers a variety of topics like

- Function principles of Power Transformers

- Function principles of On-Load Tap-Changers

- Protection devices of Power Transformers