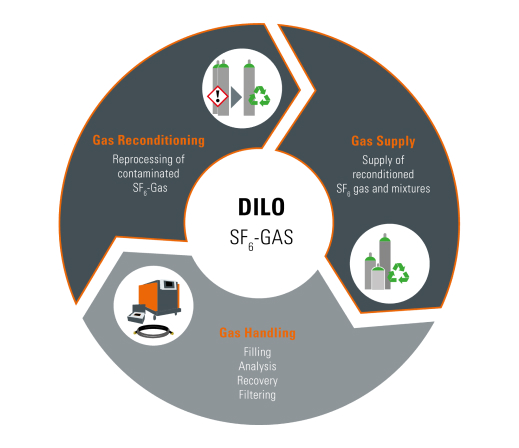

DILO is a global leader in gas handling technology, specializing in both SF6 and new alternative gases used in high-voltage (HV) applications. As the HV industry shifts from relying solely on SF6 as an insulation gas to adopting more environmentally friendly alternatives, DILO stands at the forefront of this transition. The company provides advanced equipment, services, and expertise that ensure safe and efficient gas handling, measurement, treatment and even reconditioning. DILO is driven by its commitment to sustainability and innovation in the energy sector.

- Measuring Devices

- Gas Handling Equipment

- Gas Treatment & Reconditioning

- DILO Accessories & Couplings

Measuring Devices

Depending on the individually combinable unit configuration, the following values can be determined:

- SF6 volume percentage (%)

- Moisture concentration

- SO2 concentration (ppm)

- HF concentration (ppm)

- H2S concentration (ppm)

- CO concentration (ppm)

Gas Handling Equipment

Service carts for large and extra large gas compartments

The L170 service cart has been developed to recover, evacuate, fill, purify and vent large to extra large SF6 gas compartments with high process reliability. Thus, a gas compartment with 1,000l and 5 bar pa can be recovered down to 1 mbar in only 38 minutes*) when using the DN40 coupling**). Thanks to the state-of-the art control all functions run automatically and are displayed on a 10“ touch panel. The operating software with intuitive user navigation in several languages makes operation very easy and comfortable. This service cart can be optionally operated via mobile devices such as a smartphone, tablet or laptop.

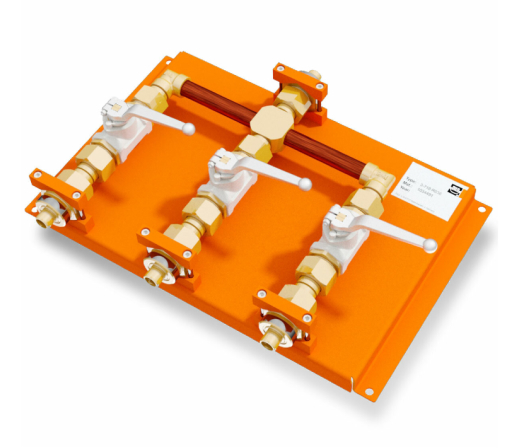

DILO Accessories & Couplings

DILO is a seal principle without intermediate seal in the form of groove and tongue with little depth of immersion. This principle guarantees permanent tightness at high static and dynamic alternating stresses which might result from vacuum and pressure in connection with high temperatures and vibrations

inside the tubing systems.

Sealing in accordance with the DILO principle is elected by direct contact with the sealing profiles of the groove and tongue parts. The different radii of curvature of the groove and tongue are in a certain

relation to each other.

Thus, two ring-shaped sealing areas are produced which create high stability.

The additional braking surface prevents plastic deformations at the ring-shaped sealing areas.

Range of application and temperature:

Reduction factors apply for the operating pressure with increasing temperature in accordance with DIN EN ISO 10380, e.g. at 100° C the 0.74 factor applies. Only conditionally suitable for use

in a marine or coastal atmosphere. Corrosion resistance tested according to IEC 60068-2-52.

UV-resistant. Increased service life and temperature resistance compared to rubber hose.

Materials and composition:

Full metal wall made of 1.4404 with outside wire sheathing made of stainless steel.

Supply length: max. 25 m

Fitting material: brass or stainless steel

For nominal diameter DN8 the clamping nut is made of stainless steel.