Maschinenfabrik Reinhausen (MR) is a global leader in control and regulation of power transformers, solutions for transformer digitalization and intelligent sensors. Known for their innovation in on-load tap-changers, MR also pioneers advanced digital monitoring systems that enhance the reliability and efficiency of power transformers. With its innovations MR is driving the future of smart grid solutions and ensuring optimal performance in electrical networks worldwide.

MR:

- On Load Tap Changes (OLTC)

- Voltage Regulation & Transformer Automation

- Motordrives, Oilfilter unit, Accessories

- Indicators

On-load Tap-changers

The compact class for distribution transformers

ECOTAP® VPD® is the solution for all operators who have to maintain voltage in a defined and stable band in public, industrial and private distribution grids. Compact and able to be standardized, with a large control bandwidth even in fine steps, for autonomous, automatic voltage regulation and a communication interface: ECOTAP® VPD® is a highly economical solution while maintenance-free over the service life of the transformer. More and more operators are therefore introducing the voltage regulating distribution transformer in to their strategic network planning. It is also perfectly suited for grid-code-compliant connection of wind or solar parks.

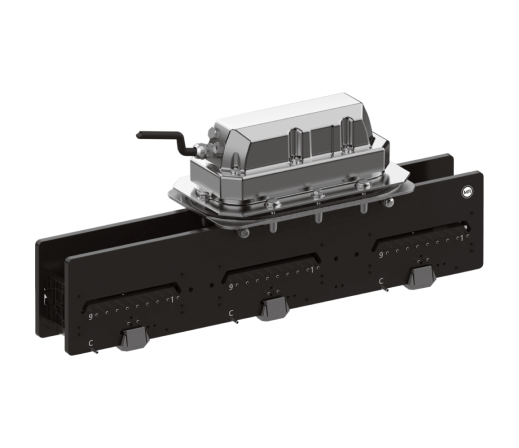

The evolution of our proven vacuum technology

The ECOTAP® VI is an innovative on-load tap-changer in vacuum technology that is used in small and medium-sized power transformers. It impresses with material savings – also on the transformer – as well as with simplified customer interfaces during installation and commissioning.

The specialist for maximum power

Universal on-load tap-changer in vacuum technology for transformers with special power requirements. VACUTAP® VR® is the most powerful on-load tap-changer in vacuum technology. It is at home wherever performance and safety are needed in grid or industrial operations.

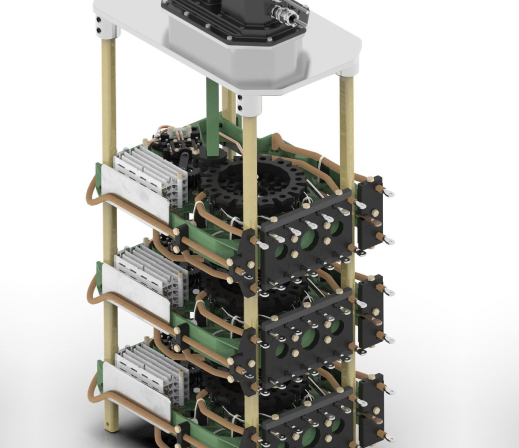

Maximum performance for high-end applications

The transformation of energy systems places enormous demands on system-critical network components such as power transformers. Our answer to this is VACUTAP® VRL® I 3201.

The world’s most powerful vacuum tap-changer is based on the further development of our proven VACUTAP®-technology. It is the first choice when it comes to:

Voltage Regulation & Transformer Automation

The easy answer to digitalization and the energy revolution

The new generation TAPCON® 230 with a new design and significantly improved hardware and software functions. The concept of the new TAPCON® 230 is designed for consistent ease of use – everywhere and in all phases of operation. Together with users, we developed an intuitive operation that requires no special training. New control algorithms, such as TAPCON® Dynamic Set Point Control (TDSC), are our answer to the increasing dynamics in the network. The result: TAPCON® 230 makes voltage control easier than ever.

Monitor. Control. Regulate.

The standalone version of ETOS® lets you evaluate and record all relevant operating data of your power transformer, such as monitoring the tap-changer or evaluating transformer utilization. ETOS® helps with focused planning of operation and maintenance. Our open ETOS® system can connect sensors from other manufacturers and combine all of the signals in a cabinet. ETOS® complements existing secondary control cabinets and tap-changer drives. Customized upgrades ensure you always have the best configuration for future tasks.

The DGA Sensor that tells you the story of your transformer. From 3,500€.

Aging transformer fleets, increasing complexity, loss of competence caused by generational change, rising energy demand, and increasing volatility are challenging our electrical energy networks, and new solutions in operational and strategic asset management are needed.

Asset and service managers at utilities, power generators and industrial power grids around the world have an increasing number of tasks and challenges in their daily work, such as shrinking budgets and the impact of renewable energy, combined with the need to stabilize profitability while guaranteeing reliability.

Furthermore, ISO 55000 sets further requirements for carrying out asset management activities. In order to respond to these challenges, asset managers increasingly rely on various diagnostic tools such as the dissolved gas analysis (DGA).

Fiber-optic online temperature measurement with the MSENSE® FO system

When power transformers fail, the costs can get high. Online fiber optic temperature monitoring by MSENSE® FO precisely detects the winding temperature in real time. Unlike conventional measurements, the system immediately detects a rise in winding temperature or hot spot. It is easy to integrate, robust and comprehensively processes the measured values. MSENSE® FO is the effective tool for dynamic overload management and ensures high operational reliability and efficiency.

Use vibroacoustics to analyze the heartbeat of your tap-changer

On-load tap-changers are among the most important and critical components of power transformers. It is therefore crucial for grid operators, to be able to ascertain their condition at any time. Based on our experience from over 20 years of tap-changer monitoring, we have developed a unique online diagnostic tool: MSENSE® VAM.

VAM stands for vibroacoustic measurement and this device can be used universally for all types and brands of OLTC.

Good to know: Our service goes even one step further. Our VAM ANALYSIS SERVICE offers a detailed report with recommendations and actions

Maintenance-free dehydrating breathers

Ever longer operating times and ever higher current densities lead to constantly increasing demands on operating equipment. The maintenance-free MESSKO® MTRAB® 2.5 dehydrating breathers continuously dehumidify and monitor the breathing cycle of power transformers – in all climatic zones. They regenerate themselves. This ensures maximum operating times and safety, and also massively reduces costs. The MESSKO® MTRAB® 2.5 devices have been proven over 100,000 times worldwide. The intelligent algorithm ensures that the IEC 60076-22-7 standard is complied with at all times. The MESSKO® MTRAB® 2.5 now offers an app function for easy data transfer.

Motordrives, Oilfilter unit, Accessories

Reliability meets automation

In addition to driving the tap-changer, ETOS® ED lets you evaluate and record all of the relevant operating data from your power transformer, such as monitoring the tap changer or evaluating transformer utilization. ETOS® ED helps with focused planning of operation and maintenance. The solid, proven housing protects both the motor-drive unit and the integrated monitoring system. Optional automation solutions such as voltage regulation and cooling system control can also be included in the ETOS® ED order and used as supplementary equipment for controlling the transformer.

OIL FILTER UNIT OF 100

- Paper filter design to clean the switching oil

- 2 pump unit designs are available

- Combination filter design to clean and dry the switching oil

2 designs for controlling the pump unit - Control integrated into separate control cabinet

- Control integrated into the ED motor drive

Innovative motor-drive solutions

In the ETOS® TD drive for tap changers, the energy is made available precisely where it is needed – i.e. at the tap-changer cover. The drive commands generated in the control cabinet are transmitted via a cable connection to the motor installed above. This eliminates the need for a rigid drive shaft connection and the complex and time-intensive task of installing it. What’s more, the precise motor torque delivered to the driven tap changer guarantees maximum safety when switching loads. This is because the smart drive can check all key parameters using the OLTC PreCheck function.

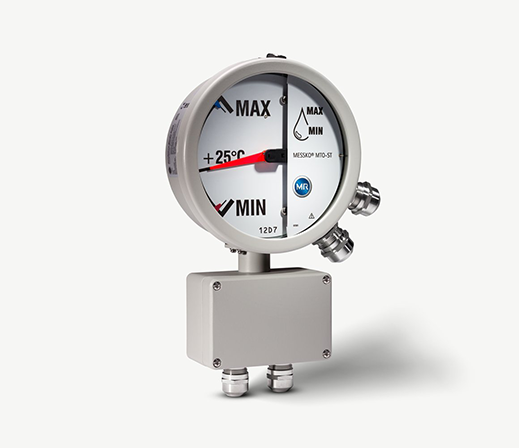

Indicators

BeTech

- Thermometer with bellow-type technology

- Extremely durable and reliable

- No readjustment or recalibration ever needed

- Contacts individually adjustable

- Compensation of ambient temperature

- Laminated safety glass viewing glass with built-in UV filter

Trasy2 – Series

- Bourdon tube measuring system with no additional mechanical parts

- Extremely durable and reliable

- No readjustment or recalibration ever needed

- Quick and easy configuration of gradients via DIP switches in the ZT-F2.1 (thermal image of winding temperature)

- Automatic compensation of ambient temperature

- Laminated safety glass viewing glass with built-in UV filter

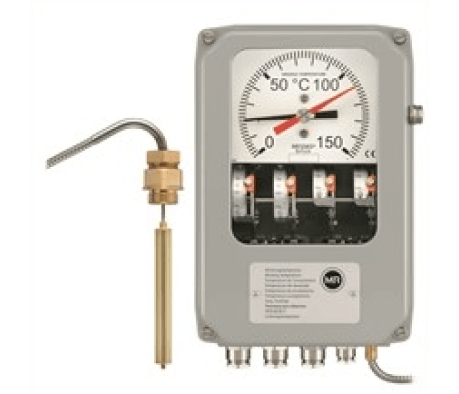

TAPMOTION ED

- Bourdon tube measuring system with no additional mechanical parts

- Extremely durable and reliable

- No readjustment or recalibration ever needed

- Quick and easy configuration of gradients via potentiometer (thermal image of winding temperature)

- Laminated safety glass viewing glass with built-in UV filter