Introduction

We are proud to have the largest HVDC testing capacity in South-East-Asia.

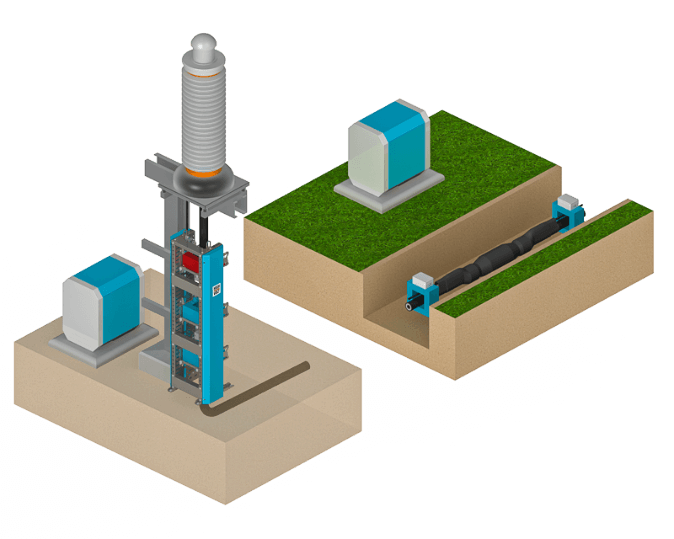

With our 800kV HVDC test system we perform on-site High Voltage DC test for

- HVDC cables up to 525kV and

- HVDC Gas Insulated Switchgears

We are professionals in High Voltage Testing and have successfully executed more than 200 High Voltage Tests.

Our assets and specialists love to travel and we have references from Middle East across South East Asia to Oceania!

HVDC Cables Testing

Testing standards are defined in IEC 62895:2017 which recommends a DC withstand test at 1,45 U0 at negative polarity for 60 minutes.

CIGRE Study Committee B1 recommends in Brochure CIGRE WG B1.32 Technical Brochure 496, “Recommendations for Testing DC Extruded Cable Systems for Power Transmission at a Rated Voltage up to 500 kV,” an on-site AC test prior to the DC withstand test to reliably identify assembly failures by means of partial discharge measurement.

In 2019, the German Standardization Organization VDE DKE referenced IEC 62895:2017 and expanded it with the technical recommendations from CIGRE TB 496, publishing the result as DIN IEC 62895:2019.

German TSOs agreed with cable manufacturers to conduct this AC resonant test at reduced test voltage of 0.5 … 0.8 U0 for 60 minutes. This procedure was introduced as only AC voltages over that time triggers PDs reliably due to assembly failure modes on accessories.

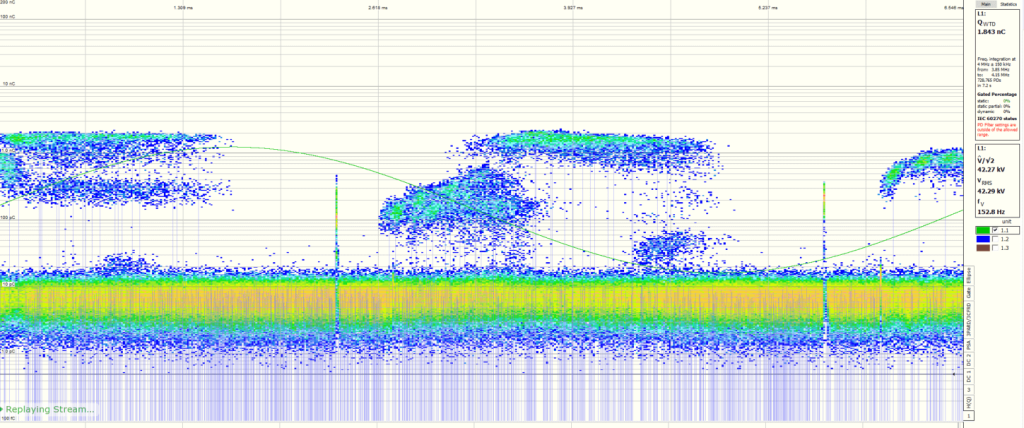

Partial Discharge Measurement

There are no standards defining Partial Discharge measurement procedures during DC tests. Nevertheless PD indication is sometimes used as early indicator before a potential breakdown.

Therefore actual practices favour an AC test prior to the DC withstand test to perform reasonable PD analysis of the cable system.

We are happy to provide you with DC and AC tests, as well as PD measurement depending on your preferences and priorities.

HVDC Land Cables

HVDC land connections enable the transport of large amounts of electrical energy over long distances. When executed using underground cables, joint connections are typically required approximately every 800 to 1200 meters. These joints are generally accessible, allowing for traditional partial discharge (PD) measurements at each joint bay during HVDC testing with the above mentioned limitations.

However, with around 130 joints for a 100 km land connection, this approach becomes highly labor-intensive and time-consuming. Additionally, the likelihood of failure increases significantly with the number of joints. A more efficient alternative is the online PD monitoring system, HiMON, which provides continuous oversight and reduces the risks associated with joint failures. This system is facilitating a measuring sensor only every 12km rather than at every joint bay.

Subsea Cables

For subsea cables, partial discharge (PD) measurements can only be performed at the end terminations. It is recommended to conduct PD measurements on both the near and far end terminations. The jointing process for the underwater joints differs significantly from that of land cables and is ultimately more reliable. As a result, the absence of PD testing at every joint location is generally considered acceptable.

Given the extended lengths of subsea cables, it is crucial to consider the sheath return current during HVAC testing (if applicable), as it may exceed the permissible limits. In such cases, the sheaths or conductors of other phases, or even the metallic return, can serve as parallel return paths to mitigate the issue.

To reduce the testing power requirements and the associated return current for such long cables, standards permit lowering the frequency for AC resonance tests to 10 Hz.

HIGHVOLT HiMON System

Your comprehensive cable monitoring system, addressing critical needs across multiple applications:

- Online Partial Discharge Measurement and Commissioning Tests:

HiMON functions as an advanced online partial discharge (PD) monitoring system, capable of detecting insulation defects in real-time. Additionally, it can be used during the commissioning high-voltage (HV) test to perform precise PD measurements. Only one sensor per 12km cable length is needed. - Online Fault Localization for Long Subsea Cables:

HiMON excels in online fault localization, particularly effective for long subsea cables. If your cable happen to suffer a failure you will immediately know at which point. HiMON was successfully used for sea cables of several 100km length with only two sensors at the near and the far end. The localization accuracy is 0.4% of the cable length. - Monitoring the Metallic Return of HVDC Lines:

HiMON provides real-time monitoring of the metallic return in HVDC systems, ensuring any damage to this critical component is promptly detected—damage that might otherwise go unnoticed. By maintaining the health of the metallic return, HiMON ensures that in the event of a pole cable failure, the metallic return is ready and reliable to carry the load and keep your system running.

With HiMON, you benefit from enhanced diagnostics, reliable fault detection, and continuous system health monitoring.